CNC Automation

Our innovative CNC pallet pool systems are designed to enhance productivity, reduce downtime, and support high-volume and low volume/high-mix production environments.

Save on labour setup costs

Skilled tradesman are no longer required to change over pallets.

Lights out machining

Just load the system and walk away.

Reliability & Quality

Local manufacturing ensures superior quality, faster delivery, and unmatched support

Customizable

We are able to customize the unit to your specifications, colour match or variations

Increasing Productivity

Reduce CNC machine spindle downtime by up to 3000%.

CNC Automation Products

We offer customized pallet changer solutions for a wide range of CNC applications. Our units cater to medium workpieces with frequent changeovers and large, heavy workpieces requiring superior weight capacity for high-volume production & low volume / high mix production. Our pallet changers are designed for seamless integration and compatibility with various CNC machines.

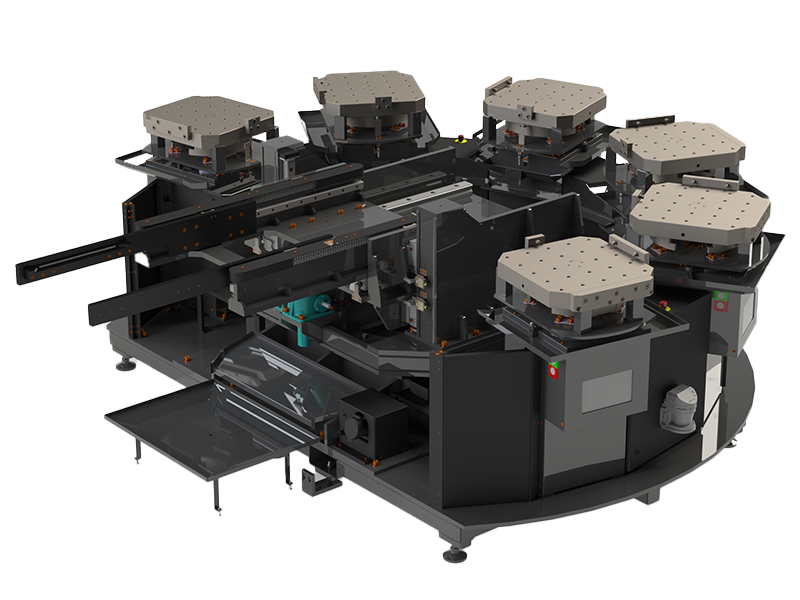

RXi1000

Maximize efficiency with our compact rotary pallet pool, delivering seamless access to every load station while optimizing floor space.

View Product

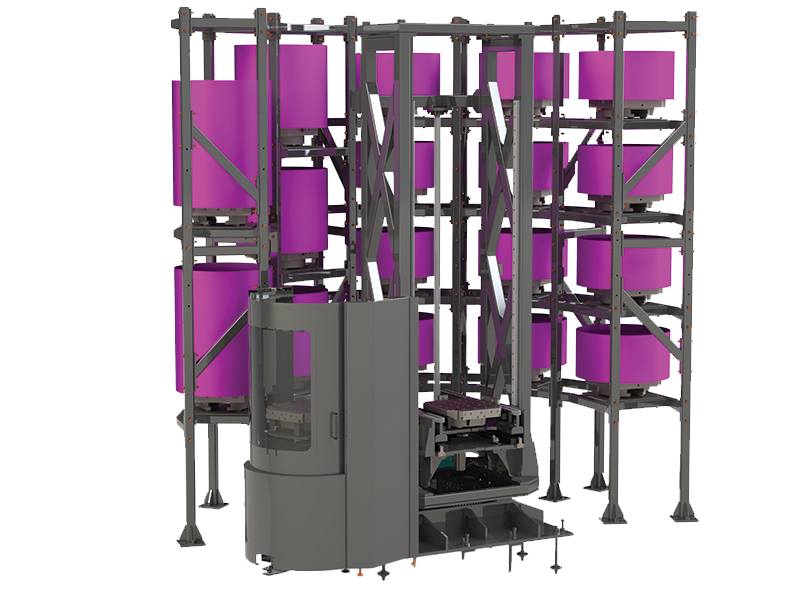

RXi1000e

Engineered for performance, this rotary pallet pool offers expanded pallet storage, designed to be the productivity powerhouse in your facility.

View Product

RXi2500

Built for heavy-duty operations, this rotary pallet pool handles your largest CNC loads with precision and reliability.

View Product

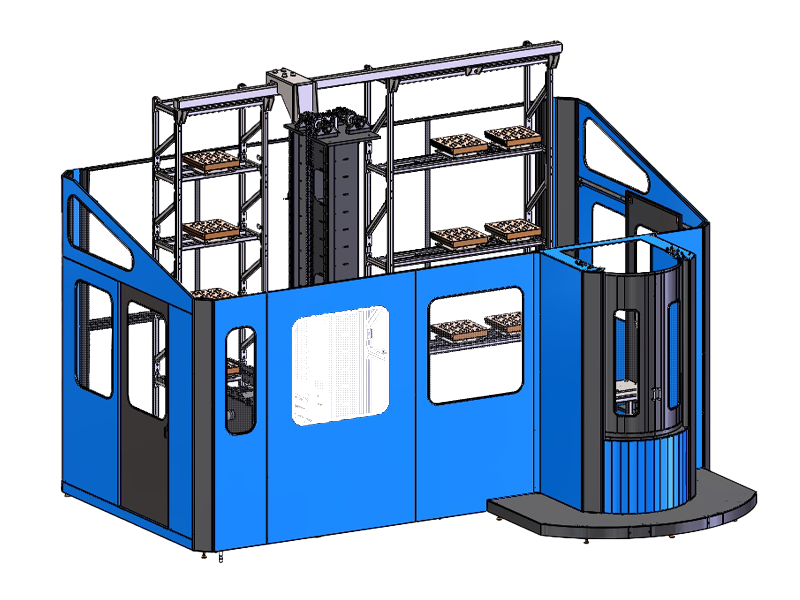

MXi500

Transition seamlessly from single-machine automation to a multi-machine system, reducing spindle downtime and boosting operational efficiency.

View Product

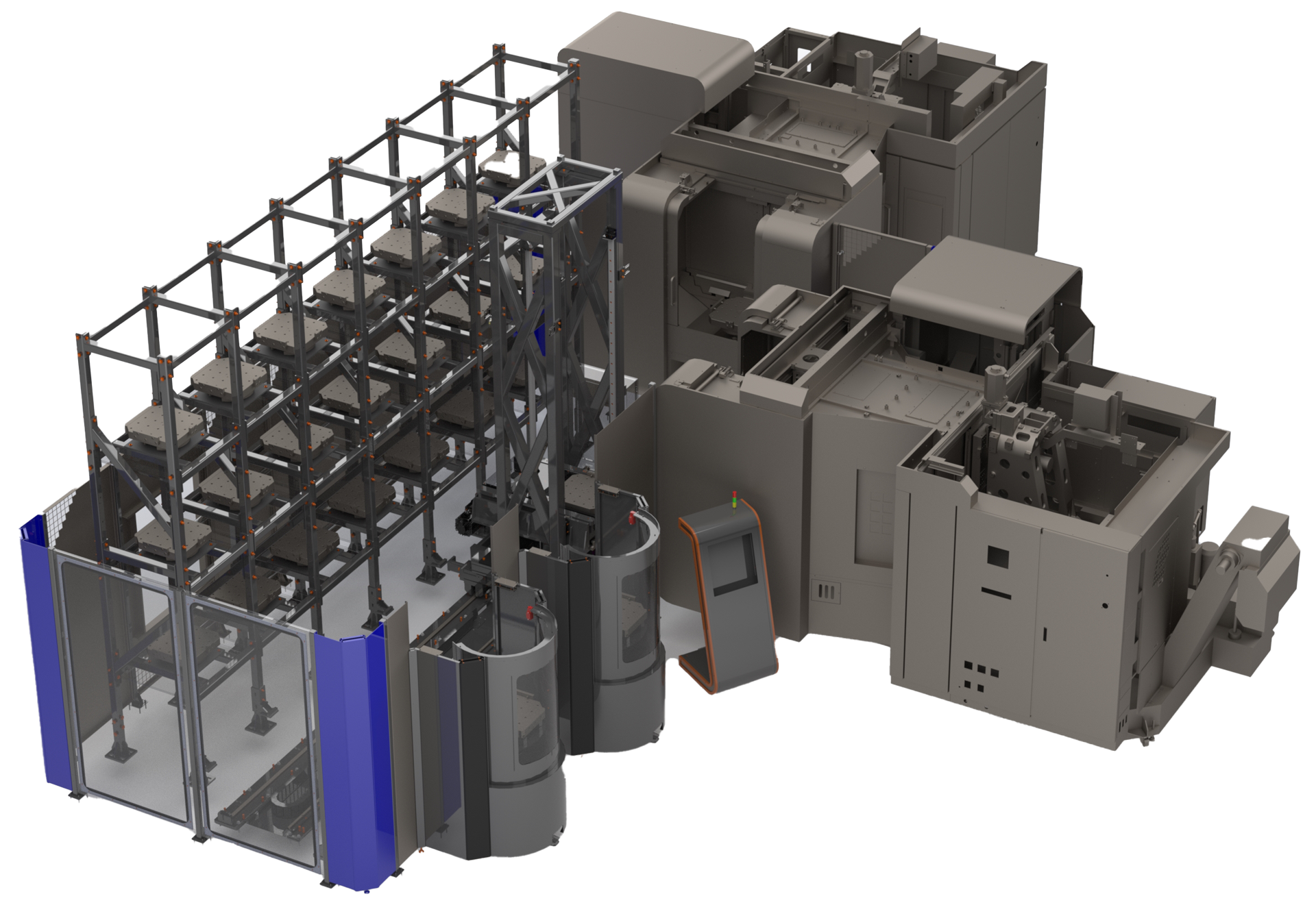

MXi1000

A versatile linear pallet pool offering four-directional loading, ideal for both high-production and high-mix/low-volume operations .

View Product

FXi500

This space-saving single-machine pallet pool ensures continuous operation, perfect for compact environments demanding high productivity.

View Product

FXi2500

Designed for unmanned 24/7 machining, the FXi2500 combines compact design with the power to lift heavy loads, ensuring optimal performance.

View ProductEND-TO-END PROCESS INNOVATION

Initial Contact & Discovery

Consultation and needs assessment to understand your operational requirements, demonstrate our automation capabilities, and determine the right solution for your needs.

Proposal & Agreement

Comprehensive summary and discussion on technical specifications, ROI analysis, payment terms, delivery schedule, and agreed-upon legal requirements to begin work.

Design & Manufacturing

Assembly and development of your [system | machines] according to your specifications with rigorous ongoing testing, ongoing quality assurance, and regular progress updates.

Installation & Commissioning

Site preparation and logistics planning for delivery, setup, and integration. Thorough performance testing and adjustments as needed for formal acceptance.

Onboarding & Handover

Training sessions on machine operation, maintenance, and safety protocols with leave-behind user manuals, maintenance guides, and troubleshooting tips.

Ongoing System Support

Technical support and maintenance services for regular check-ins to resolve any issues and ensure ongoing performance satisfaction.