The Future of CNC Automation

Thursday September 18, 2025

477 Highway 77, Leamington, ON N8H3V6 519-325-1005 Ext. 223

View All NewsThe manufacturing industry is at a turning point. For decades, CNC machining has been the backbone of production — delivering precision, repeatability, and scalability. But as demand grows and global competition intensifies, the question is no longer whether automation belongs in CNC machining. The question is how quickly shops can adapt to it.

At Uni-Fab Automation, we see the future of CNC automation unfolding in ways that will redefine productivity, employee experience, and the way manufacturers compete.

Why CNC Automation Matters Now More Than Ever

Manufacturers today face three major challenges:

- Skilled labor shortages. Finding and retaining experienced machinists is harder than ever.

- Global competition. Shops are expected to deliver higher quality, faster, and at lower cost.

- Demand for flexibility. Customers want shorter lead times and smaller batch runs without sacrificing precision.

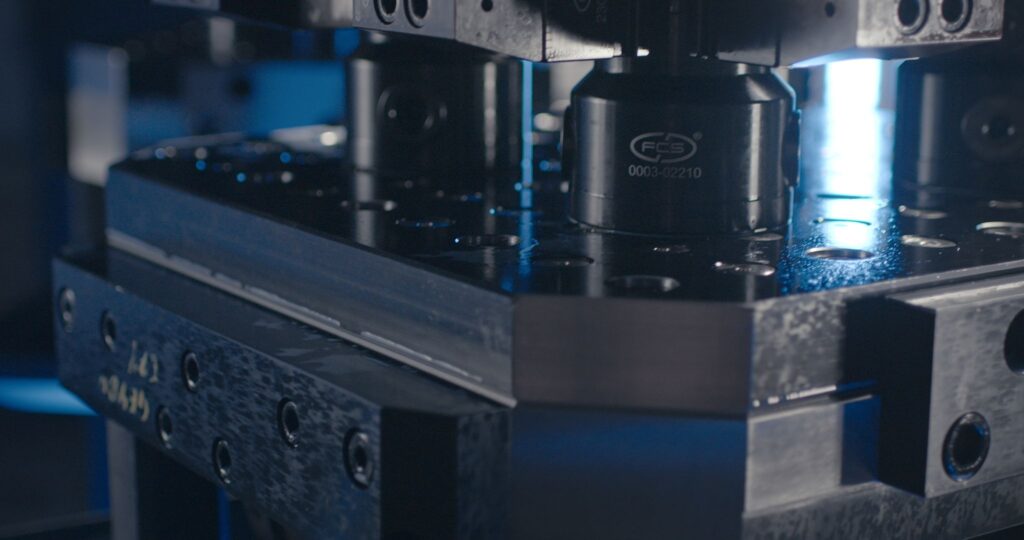

Traditional CNC machining alone can’t keep pace with these demands. Automation — through pallet changers, pallet pools, and integrated systems — extends machine uptime, reduces setup time, and allows skilled workers to focus on what they do best: problem solving, programming, and quality assurance.

What the Future Looks Like

The future of CNC automation isn’t about replacing people. It’s about amplifying human capability with smart systems that run reliably, consistently, and safely. Some of the key shifts we see shaping the industry include:

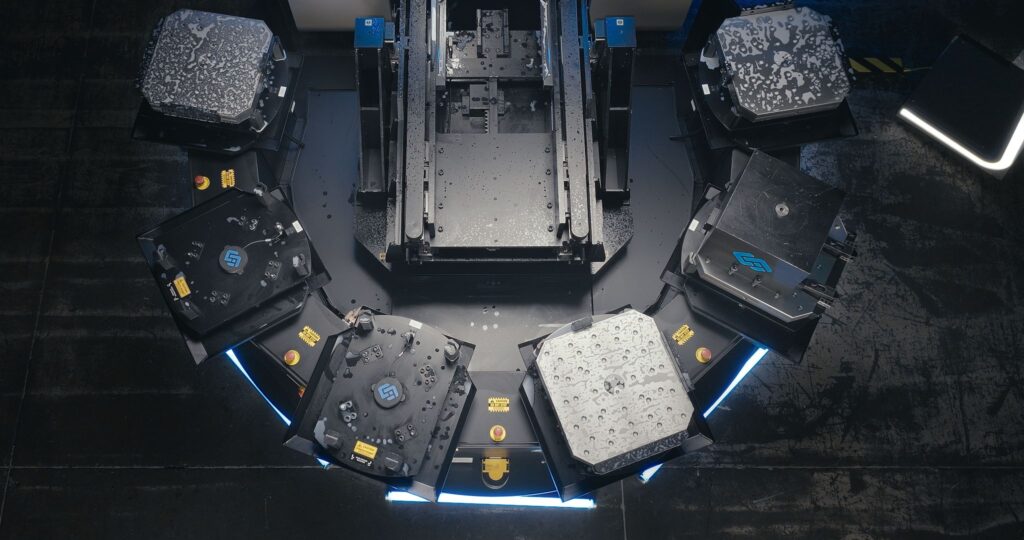

- Lights-Out Manufacturing: Systems designed to run unmanned for entire shifts, increasing spindle utilization from 30–40% up to 80% or more.

- Scalable Pallet Systems: Modular automation that grows with a shop — from a single pallet changer to multi-machine linear pallet pools.

- Seamless Integration with CNC Controls: Modern automation communicates directly with CNC controllers like Fanuc, Siemens, Heidenhain, and Mitsubishi via protocols such as Profinet, enabling smoother workflows.

- Data-Driven Operations: The next phase will bring advanced monitoring, predictive maintenance, and real-time analytics — empowering smarter decisions on the shop floor.

The Human Side of Automation

Too often, automation is seen as a threat to jobs. The reality is different. Automation reduces repetitive, physically demanding work — giving machinists more time to focus on value-added tasks like programming, process optimization, and innovation.

Shops that adopt automation often see:

- Happier employees who no longer spend hours loading/unloading heavy parts.

- Career growth opportunities as operators become automation specialists.

- Improved safety with reduced risk of repetitive strain injuries.

Uni-Fab Automation’s Vision

Our mission at Uni-Fab Automation is to make CNC automation accessible, reliable, and scalable. We design and build pallet changers and pallet pool systems that integrate seamlessly with a wide range of CNC machines. Whether you’re running a single machining center or planning a multi-machine automation line, we provide solutions that:

- Boost productivity by maximizing spindle utilization.

- Fit your workflow with modular, expandable layouts.

- Secure your future with systems designed to grow as your business grows.

We’ve seen firsthand how automation transforms shops — not only in output but in the way teams approach work. The future of CNC automation isn’t about eliminating people; it’s about empowering them to take manufacturing to the next level.

Where to Begin

Every journey starts with a first step. For many shops, that step is as simple as adding a pallet changer to a single CNC machine. From there, automation can scale naturally — expanding capacity, reducing downtime, and unlocking new levels of efficiency.

If you’re ready to explore what automation could mean for your shop, Uni-Fab Automation is here to help.

📩 Contact us today to learn how we can shape the future of CNC automation together.